MAXIFLEX SPIRAL WOUND GASKETS

Maxiflex spiral wound gaskets have the ability to recover under the action of fluctuating loads caused by process fluid pressure and temperature changes, flange face temperature variations, flange rotation, bolt stress relaxation and creep.

MAXIFLEX SPIRAL WOUND GASKETS

Maxiflex spiral wound gaskets have the ability to recover under the action of fluctuating loads caused by process fluid pressure and temperature changes, flange face temperature variations, flange rotation, bolt stress relaxation and creep. The gasket sealing element consists of a pre-formed metallic winding strip with layers of a softer, more compressible sealing material which, during compression, is densified and flows to fill imperfections in the flange surfaces. The metal strip holds the filler giving the gasket mechanical resistance and resilience.

Product Advantages

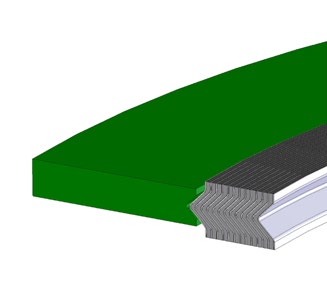

Maxiflex spiral wound gaskets combine the ease of sealing a graphite, PTFE or mica filler with the strength afforded by a specially profiled metallic, spring-like reinforcement. The sealing element is manufactured by interleaving plies of alternating metallic winding strip and filler to create a gasket that is robust and easy to install. Maxiflex spiral wound gaskets create a very tight and reliable seal suitable for high temperature and pressures and can be manufactured to suit standard flanges and also custom-designed vessels.

Maxiflex gaskets are capable of giving an excellent seal over a wide range of flange surface finishes, but as a general guide we suggest under general duties, a flange surface finish of 125-248 μin (3.2 - 6.4 μm)

Maxiflex Spiral Wound Gasket Construction

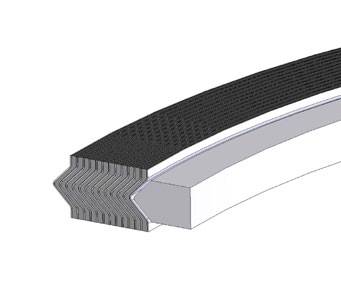

Several layers of specially formed continuous chevron-shaped metal strips are spirally wound with alternate plies of soft filler strip to make the gasket’s basic sealing element. The chevron profile allows the gasket to act as a spring and the depth is carefully controlled to give the sealing element the best compression and recovery characteristics. Maxiflex spiral wound gaskets are manufactured to specifications of ASME B16.20.

Computer controlled winding machines carefully monitor and adjust the tension of the winding strips. A uniform density throughout the product is produced. This provides the spring like action within the gasket that resists buckling and maintains a seal even when subject to fluctuating compressive loads.

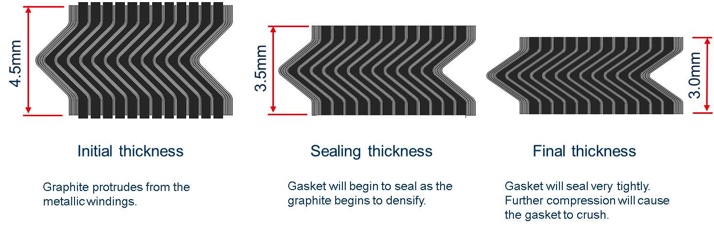

Maxiflex Thickness After Installation

Spiral wound gaskets are manufactured in a number of standard thicknesses which are designed to compress to a specific thickness to attain the best sealing performance and adaptation to the flanges. The thickness is measured to the metallic windings not to the filler.

Applications

Spirals wound gaskets are widely used in piping and pressure vessel flange connections, in medium to high pressure and temperature duties.

The sealing element of a spiral wound gasket is manufactured from a preformed metallic strip in combination with a soft filler material.

Inner and / or outer rings can be incorporated to suit the flange face design and application parameters.

Dimensions

The dimensional requirements for spiral wound gaskets are provided in ASME B16.20 for various flange standards.

Gaskets are also available to meet the dimensional requirements of other flange standards, such as EN or JIS.

Custom sized gaskets can be produced from customer supplied information.

Three standard sealing element thickness options are available, i.e., 0.125", 0.175" and 0.250". Other thicknesses are available on request.

Materials

Sealing element winding strip: Austenitic and duplex stainless steel grades as well as other exotic alloy steels.

Sealing element filler material: Flexible graphite, PTFE and mica.

Custom sized gaskets can be produced from customer supplied information.

Three standard sealing element thickness options are available, i.e., 0.125", 0.175" and 0.250". Other thicknesses are available on request.

Style R - Sealing element only

Wide choice of materials for filler and metallic strip

Suitable for high pressure and high temperature applications

Recommended flanges: tongue and groove, male to female and flat face to recess in vessels, valves and pumps

General and critical duties

Style CR - Sealing element with outer ring

Solid metal outer ring used as a centering device and compression stop

Used mainly on raised face and flat face flanges

Wide choice of material for filler and metallic strip

General duties

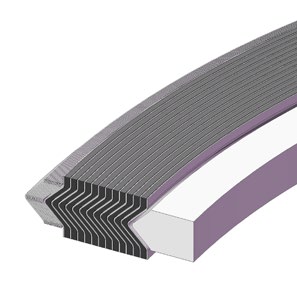

Style CRIR - Sealing element with inner and outer ring

Solid metal inner and outer rings

Suitable for high pressure and high temperature applications

Standard spiral wound gasket for raised face or flat flanges

Prevents turbulence and erosion damage to flange

Prevents damage to the gasket bore and inner windings

Inner ring acts as a heat shield and corrosion barrier

Wide choice of material for filler and metallic strip

General and critical duties

Style RIR - Sealing element with inner ring

Solid metal inner ring

High pressure and high temperature capability

Male to female flanges in vessels, valves and pumps

Wide choice of materials for filler and metallic strip

General and critical duties

Style HTX - Style RIR with inner ring and centralizing overwind

A combination of inner and outer rings

The inner ring could have pass bars or carry either a metal clad or soft gasket with pass bars

Manufactured to customer designs

Wide choice of materials for filler and metallic strip

Manufactured with thin outer windings to create stable, large diameter gaskets for narrow heat exchanger applications

Maxiflex Pro - Style CRIR with Maxiprofile inner ring

High integrity, dual seal gasket specially designed for service in highly critical, corrosive applications where sealing performance is of paramount importance

Recommended for use in highly aggressive chemical applications